Pattern detection in sewage plant

The treatment of sewage requires impressively complex plants. The biology and chemistry involved has a high inertia but the plant has to cope with short-term events e.g. a rapid increase in volume flows during heavy rainfalls. A multitude of valves, actuators, pumps and sensors are required to operate and monitor the proper functioning. A human operator allone is clearly unable to manage the control of a sewage plant and has to be assisted by automated control mechanisms. This is almost the ideal application for a data-driven approach based on self-learning algorithms.

Our first step together with our customer was to ensure the availability of the data and to ensure its mapping to physical components. Although this may sound easy, understanding the very heterogeneous data based on very little information is a tedious but important task. The next step was to put the data in a workable format. The setup was configured to allow for manually recorded data from servicing or meteorological data at a later stage.

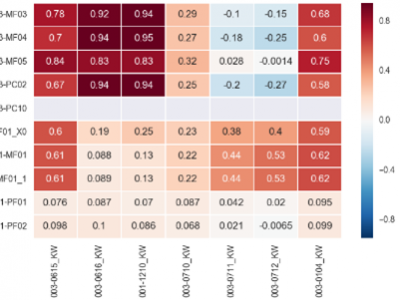

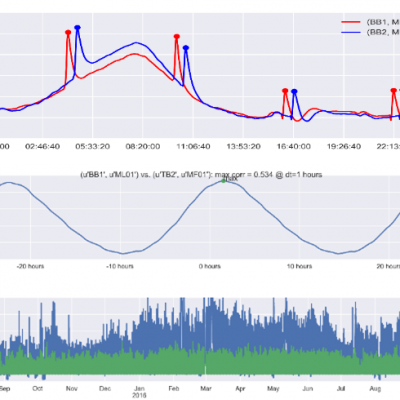

A first data analysis included both the statistical analysis (e.g. counting of on/off events, detection of maximum and minimum levels) and the correlation between the signals. This phase already identified strongly related effects and yielded valuable information about the usage on a component level for the operator. This first analysis also allowed performing very important plausibility checks by comparing the identified correlations and numbers with common sense, the available data and the operator’s experience.

Together with the operator we are now in the progress of identifying important questions that we want to answer and singular events that should be predicted.