ProCap: Ultrasonic 3D flow probe for low-speed applications

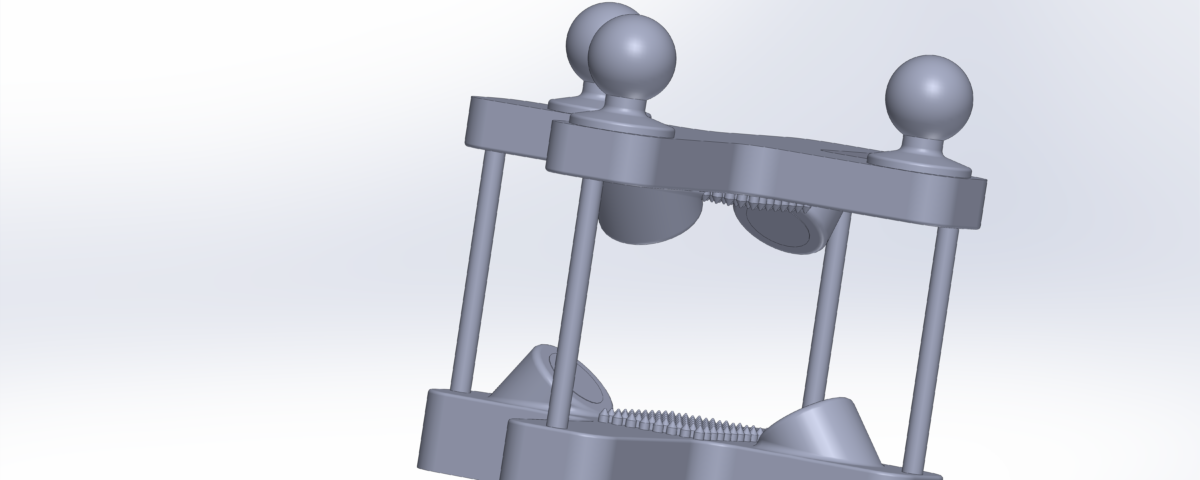

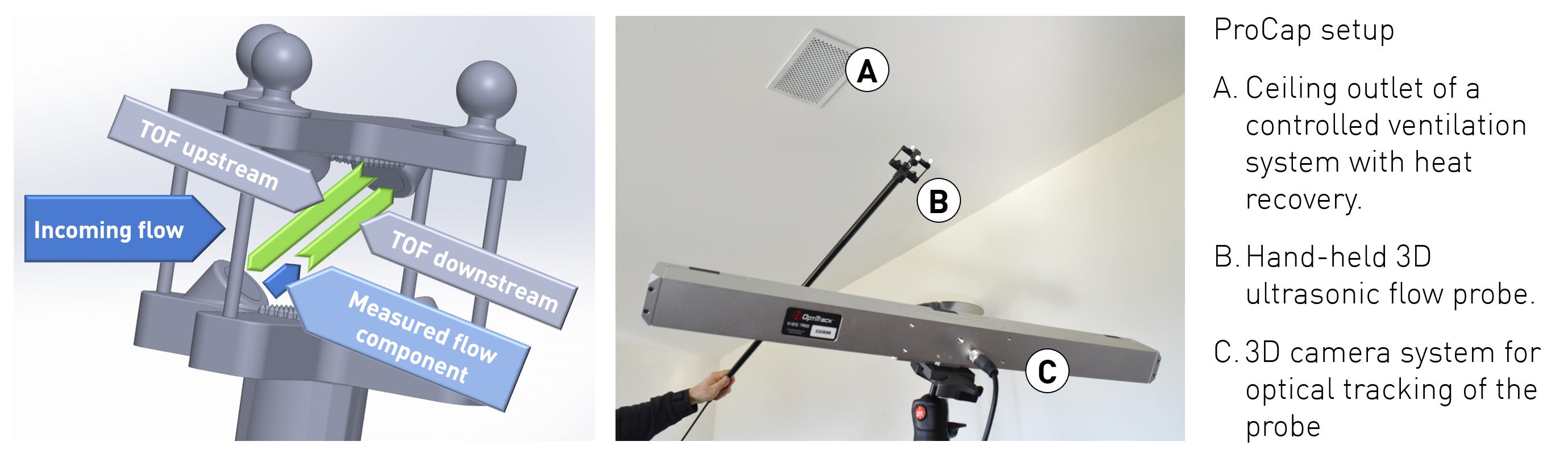

ProCap lets you scan and paint flow fields in real time. It can be used with a variety of flow probes, including 3D ultrasound anemometers. These probes detect even very low velocities which are typical for indoor ventilation and air-conditioning applications.

A quick introduction to sonic flow probes

Ultrasonic anemometers are based on time of flight (TOF) measurements between opposite ultrasonic transducers. Without flow, the TOF is equal for both directions. If a flow is present, the signal travelling against the flow (upstream) is delayed while the signal downstream travels faster. From the time difference between up and downstream TOF the velocity component pointing in the direction of the signal path can be calculated. Multiple transducer pairs allow to measure more than one velocity component.

The TriSonica™ Mini sensor from Anemoment uses two pairs of transducers with 4 possible paths and can measure all 3 components of the flow (with some restrictions to the acceptance angle due to the structure). Additional sensors for ambient pressure, temperature and humidity are fitted and allow to calculate the fluid density.

Some remarks about low-speed indoor air flows

Indoor air flows are typically low-speed convection-driven turbulent flows with few regions of directed and stationary flow (e.g. near ventilation in- and outlets, open windows, etc.).

The large-scale turbulent fluctuations can easily reach peak velocities that are similar to the directed, stationary flow velocities near an inlet (0.1 – 0.3 m/s). The timescale of these fluctuations is in the order of seconds which requires significant averaging times or multiple passes with the probe for the stationary flow pattern to emerge in the data.

And most importantly, ProCap’s correction for the probe’s movement based on the tracking is absolutely crucial for low-speed measurements!

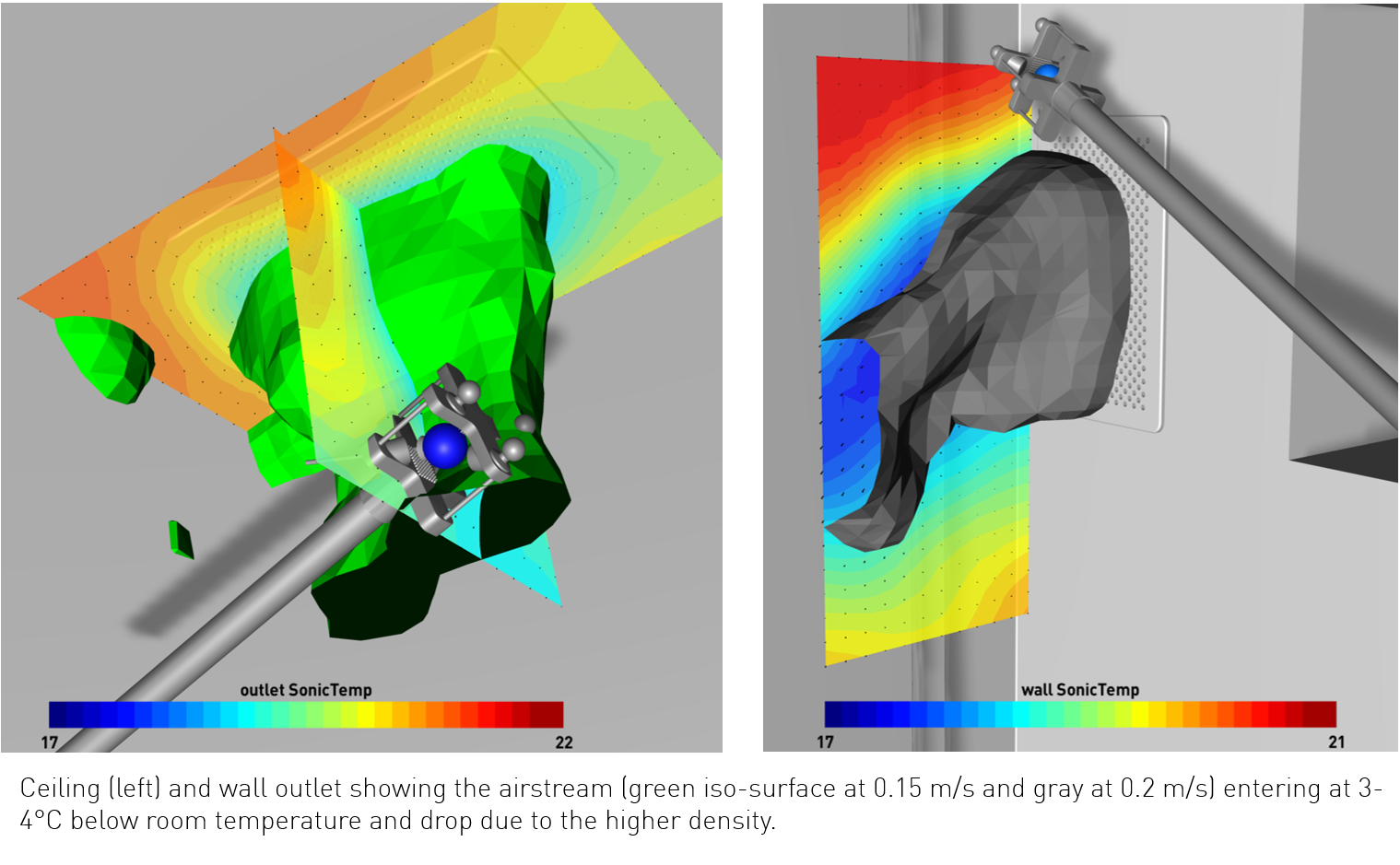

Ceiling and wall outlets of the ventilation

We measured at different locations in an apartment with a controlled ventilation and heat recovery system. Room temperature was at 21°C with an outside temperature around 10°C. Pre-heated by the heat exchanger, the fresh air is expected to enter the apartment a few degrees below room temperature through the inlets (150 by 250 mm) mounted on the wall or the ceiling.

With the unique capability of the ProCap setup to measure velocity and air temperature simultaneously, the flow structure and temperature distribution around the inlets is captured very nicely showing the capability of resolving speeds below 0.1 m/s.

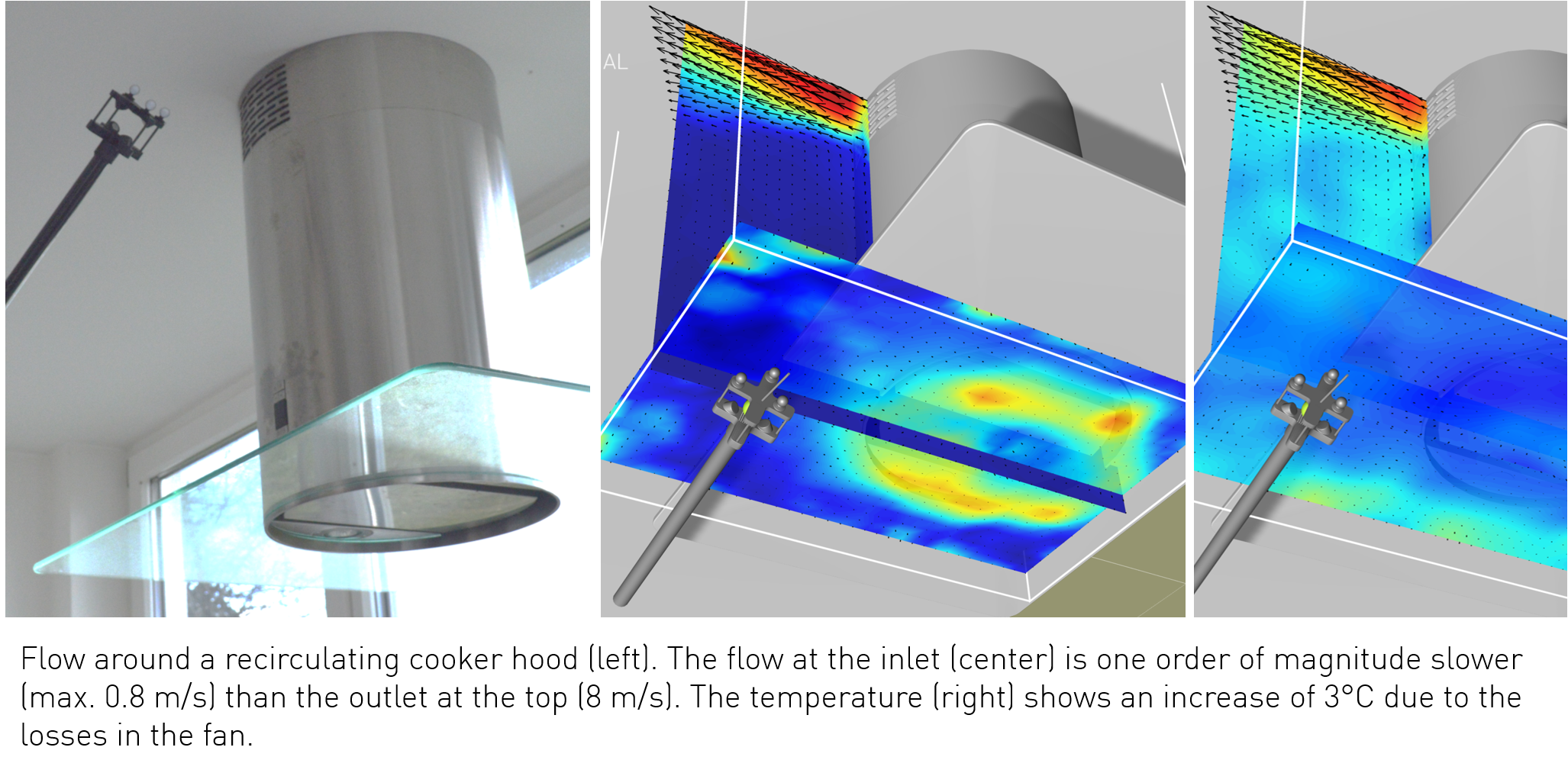

Recirculating cooker hood

Different phenomena can be investigated around the recirculating cooker hood with this unique probe. The flow is characterized by a one order of magnitude difference in the measured flow velocity at the inlet (0.8 m/s) and the outlet at the top (8 m/s). This illustrates well that especially inlets are hard to measure as the velocity decreases rapidly with increasing distance from the opening. Nevertheless, the ProCap data shows a distinct pattern a few centimeters below the hood.

It can be observed that the temperature of the flow increases 3°C between inlet and outlet. As no cooking was going on during the measurements, this can only be a result of the fan’s energy losses heating up the air.

Conclusions

ProCap with a 3D ultrasonic flow probe has a huge potential to understand and optimize low-speed flows as encountered in clean-rooms, fume hoods or room ventilation. As no tracer particles are needed and with its quick and flexible setup the measurement can take place anywhere, even in the presence of humans. The capability of the probe to not only measure velocity but also temperature and humidity increases the capabilities further.