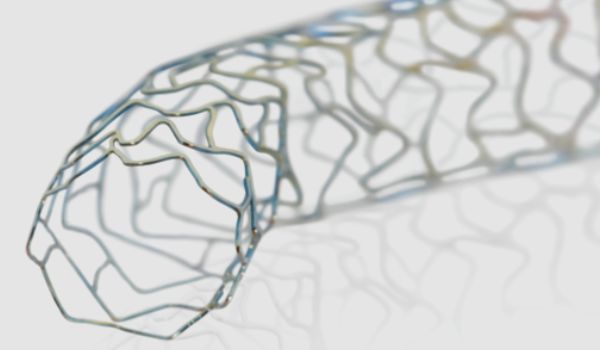

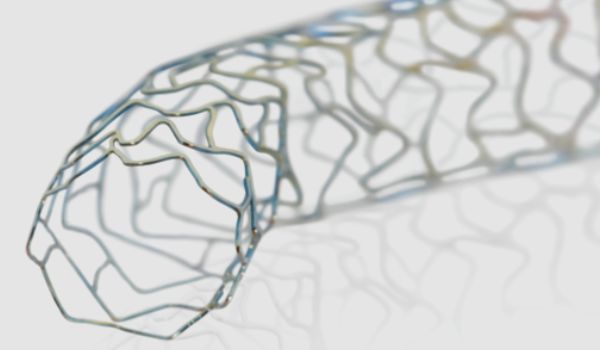

BIOTRONIK | Stent coating

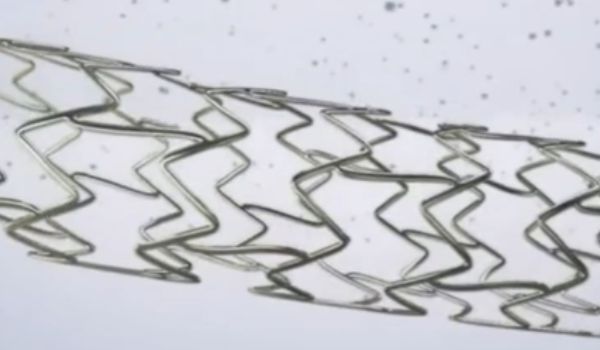

As one of the world’s leading manufacturers of cardiovascular and endovascular medical devices, BIOTRONIK is represented in over 100 countries by a global workforce of more than 5,600 employees worldwide. To date, several million patients have received BIOTRONIK implants designed to save lives and improve quality of life. BIOTRONIK produces a full range of stent systems, balloon catheters, and guidewires for patients with coronary and peripheral artery disease designed to restore the blood flow in narrowed or blocked vessels. For drug eluting stents, the coating process is a critical production step and is subject to the highest quality standards. To further improve the quality and efficiency of this step, BIOTRONIK contracted streamwise to analyze the spray geometry and droplet formation in order to derive mechanisms to improve control over both.

APPROACH

streamwise analyzed the coating step in detail to understand the requirements and constraints of the process in the respective production environment. Through in-depth analysis of the excellent and extensive experimental data and laboratory protocols supplied by BIOTRONIK we were able to formulate fluid-mechanical hypotheses on the underlying physical principles, i.e., multiphase physics.

A procedure (involving modeling a subsystem for numerical simulations and further analysis of the data) to verify the predominant effects and the mechanisms to control the relevant parameters was outlined.

SOLUTION

This approach allowed us to very efficiently generate an understanding of the underlying fluid mechanical principles and to propose design modifications. Crucial for the success of the project was that streamwise was able to observe the verification at the customer’s laboratory and to refine the design together with BIOTRONIK.

As a result, the coating process is now more stable, and an increase in productivity could be achieved.